Description

Micro-Mesh Tri-Grade Buffers. Double-sided buffers featuring Ultra-Flex Micro-Mesh Regular abrasive. Abrasive is laminated with 1/32” foam and has a flexible .060 styrene core.

The Micro-Mesh 3-Way Flexi-File comes with three grades of abrasion to work up to a very smooth final finish.

One side has two abrasive grades and the other side is used for Final Finishing.

The file is designed to build up to the final finish of a piece. Perfect for many hand applications, for example, finger nails, removing parting lines on molds and polishing small areas that need touching up.

Available in 3 sizes:

- 1/2” x 5 3/4”

- 5/8” x 5 3/4”

- 11/16” x 7”

Use Micro-Mesh Tri-Grade Buffers in this order:

- Roughest: PINK or BLACK: 2400

- Medium: WHITE: 4000

- Smoothest: GREY: 12000

1/2” x 5 3/4” – Nato Stock Number (NSN):

- 4N0421 – 5350-01-337-3047

For more details on Micro-Mesh and it’s uses, click here.

Have a question or query? Contact Us

MICRO MESH THE NON ABRASIVE ABRASIVE

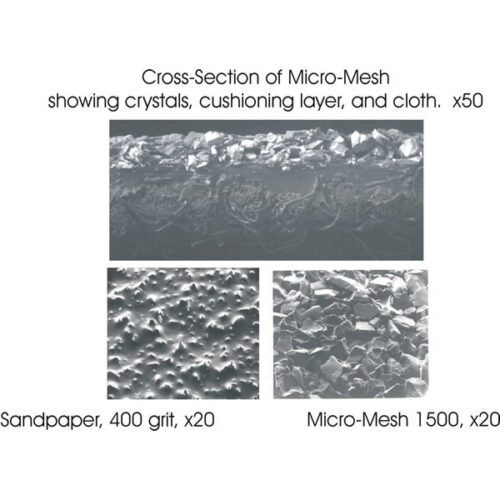

Conventional sandpaper is designed to be aggressive so that it will dig deeply. In its manufacture, the crystals are electrically charged so that they will stand up. They are locked into a hard resin and when applied to a surface it will literally tear in and remove the substrate of the material you are sanding. The crystals cut in a negative raking motion, leaving inconsistent scratch patterns.

Therefore, Micro Mesh does the opposite:

- The backing is a long lasting cloth to which an ultra flexible cushioning layer is applied.

- This cushioning layer will determine how far you can push the crystals before they will penetrate the cushioning layer.

- On top of this layer, is a very resilient glue and not a hard resin, but a completely flexible glue that will hold the crystals while allowing it to move and rotate.

- The crystals can turn in any direction without coming loose.

- When you start to apply pressure to sand with Micro-Mesh, the crystals will go into the cushioning layer while beginning to cut a bit.

- If you push harder, they will go further into the cushioning layer, which serves as a safety valve.

- It determines how much pressure you can exert in a downward direction. Instead of a deep scratch that sandpaper makes, Micro-Mesh produce a refined scratch that is close to an RMS of 1.0.

- The cushioning layer also allows the crystals to cut with a planning motion that leaves an extremely consistent scratch pattern and allows you to achieve extraordinary levels of gloss.

- In conclusion, Where conventional abrasives will take surfaces down 2 or 3 thousandths (.002 or .003), Micro-Mesh will take it down one ten-thousandth (.0001) or less.

Reviews

There are no reviews yet.