Description

The micro-Mesh Burn Kit is used to restore cultured marble, solid surface, fibreglass and acrylic with this kit. Removes burn marks, stains, discolourations, scratches and surface defects. Great for restoring vanities, sinks, tubs and tub surrounds.

The Micro-Mesh Burn Kit includes the following:

- 1500 – 3″ x 6″ Sheet Micro-Mesh

- 1800 – 3″ x 6″ Sheet Micro-Mesh

- 2400 – 3″ x 6″ Sheet Micro-Mesh

- 3600 – 3″ x 6″ Sheet Micro-Mesh

- 4000 – 3″ x 6″ Sheet Micro-Mesh

- 6000 – 3″ x 6″ Sheet Micro-Mesh

- 2 ounce bottle Micro-Gloss liquid abrasive

- 3″ x 3″ sanding block

- Cotton flannel cloth – 2 Pack

- Instructions

All types of MICRO-MESH are manufactured utilizing Ultra-Flex technology, Click Here for more details.

Each type is:

long lasting

cushioned

extremely flexible

re-useable.

MICRO MESH THE NON ABRASIVE ABRASIVE

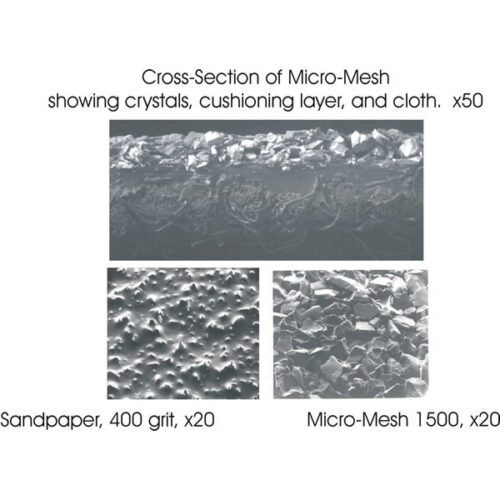

Conventional sandpaper is designed to be aggressive so that it will dig deeply. In its manufacture, the crystals are electrically charged so that they will stand up. They are locked into a hard resin and when applied to a surface it will literally tear in and remove the substrate of the material you are sanding. The crystals cut in a negative raking motion, leaving inconsistent scratch patterns.

Micro Mesh does the opposite:

- The backing is a long lasting cloth to which an ultra flexible cushioning layer is applied.

- This cushioning layer will determine how far you can push the crystals before they will penetrate the cushioning layer.

- On top of this layer, is a very resilient glue and not a hard resin, but a completely flexible glue that will hold the crystals while allowing it to move and rotate.

- The crystals can turn in any direction without coming loose.

- When you start to apply pressure to sand with Micro-Mesh, the crystals will go into the cushioning layer while beginning to cut a bit.

- If you push harder, they will go further into the cushioning layer, which serves as a safety valve.

- It determines how much pressure you can exert in a downward direction. Instead of a deep scratch that sandpaper makes, Micro-Mesh produce a refined scratch that is close to an RMS of 1.0.

- The cushioning layer also allows the crystals to cut with a planning motion that leaves an extremely consistent scratch pattern and allows you to achieve extraordinary levels of gloss.

- In conclusion, Where conventional abrasives will take surfaces down 2 or 3 thousandths (.002 or .003), Micro-Mesh™ will take it down one ten-thousandth (.0001) or less.